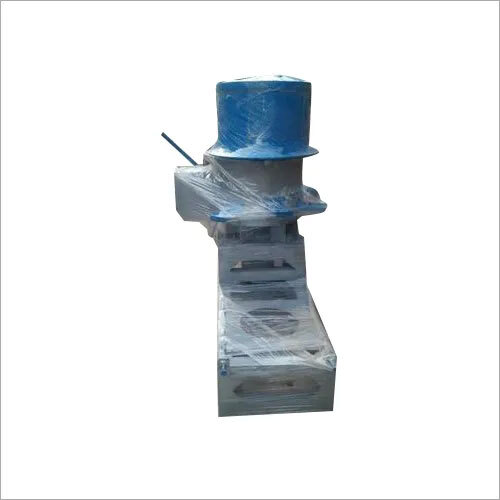

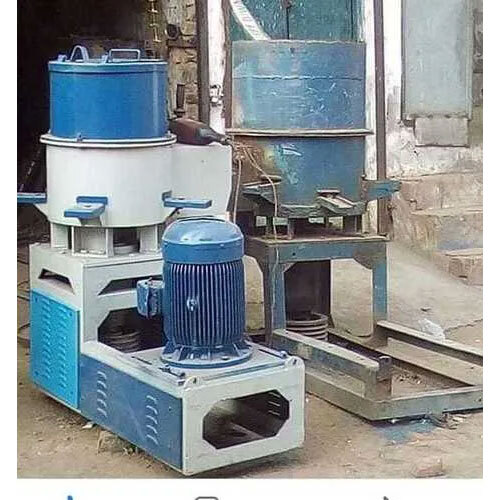

Plastic Agro Mixture Machine

125000.00 INR/Unit

Product Details:

- Lubricating System Auto Lubrication

- Drive Belt Drive

- Machine Type Plastic Mixer

- Operating Temperature 0C to 50C

- Motor Power 2 HP

- Plastic Processed Granules

- Accuracy 2%

- Click to View more

X

Plastic Agro Mixture Machine Price And Quantity

- 125000.00 INR/Unit

- 1 Unit

- Available with wheels

- Overload Protection

- Removable Hopper

- Up to 90%

- 150 L

- Onsite support available

- Plastic body with metal reinforcements

- Floor Mounted

- Polywrap and Crate

- Tirupati Plastics

- Stainless Steel

- 60 rpm

- Low

- Manual Discharge Valve

Plastic Agro Mixture Machine Product Specifications

- Plastic Agro Mixture Machine

- Robust Construction, Efficient Mixing, Easy Cleaning

- Below 70 dB

- Air Cooled

- 50 Hz

- Electric

- 1.5 kW

- Mild Steel Frame

- 200-300 kg/hr

- Semi-Automatic

- Manual

- PAMM-200

- Blue & Grey

- 120

- 220V

- 850 x 650 x 1200 mm

- Standard Atmospheric

- Belt Drive

- Plastic Mixer

- Auto Lubrication

- Powder Coated

- Granules

- 2%

- 0C to 50C

- 2 HP

- Mixture Technology

- Used for mixing agro chemicals, pesticides, and plastic granules

- 2 HP

- Available with wheels

- Overload Protection

- Removable Hopper

- Up to 90%

- 150 L

- Onsite support available

- Plastic body with metal reinforcements

- Floor Mounted

- Polywrap and Crate

- Tirupati Plastics

- Stainless Steel

- 60 rpm

- Low

- Manual Discharge Valve

Plastic Agro Mixture Machine Trade Information

- 1 Unit Per Day

- 1 Week

Product Description

A Plastic Agro Mixture Machine can be used to cut and recycle, garbage bags, milk pouches and carry bags. The agglomerators are perfectly suitable to convert film scraps of HM, HDPE, LDPE, Tapes Rafia and many others into dense pellets for convenient feeding into extruder. The machines are known for long service life and trouble free operation. Manufactured from high grade material, the machine can handle heavy loads and rough usage. The Plastic Agro Mixture Machine is very effective and useful.

Efficient Mixing Technology

Equipped with a stainless steel mixing blade and semi-automatic controls, the machine ensures thorough mixing of chemicals and granules. Operating at a steady speed of 60 rpm, users benefit from consistent performance across various agro materials.

Designed for Durability and Portability

The machine boasts a robust plastic body enhanced with metal reinforcements and a powder-coated frame. Floor-mounted with wheels for portability, it suits demanding industrial environments while remaining easy to relocate when required.

User-Friendly Operation and Maintenance

Featuring a removable hopper, manual discharge valve, and auto lubrication system, users find cleaning and maintenance straightforward. Its overload protection and air-cooled system support safe, prolonged operation under high humidity conditions.

FAQs of Plastic Agro Mixture Machine:

Q: How do I operate the Plastic Agro Mixture Machine PAMM-200?

A: Simply load materials into the removable hopper, set the control system manually, and activate the mixing process. The machine is semi-automatic and easy to operate, with a manual discharge valve for emptying the mixed contents.Q: What types of materials can this machine process?

A: The machine is designed for mixing agro chemicals, pesticides, and plastic granules, accommodating a wide range of substances commonly used in agricultural and industrial settings.Q: Where can the machine be installed and used effectively?

A: This floor-mounted mixer is suitable for installation in agricultural warehouses, processing plants, and industrial facilities. Its portable design with wheels allows flexible placement on-site.Q: What safety features does the PAMM-200 offer during operation?

A: The mixer is equipped with overload protection to prevent motor damage, and its enclosed plastic body with metal reinforcements ensures safe operation even in humid conditions.Q: How does the machine benefit users in terms of efficiency and maintenance?

A: Users gain from efficient mixing, with a high production capacity and low energy consumption. The removable hopper and auto lubrication make maintenance and cleaning hassle-free, minimizing downtime.Q: When should I clean or maintain the mixer, and what is the process?

A: Regular cleaning is recommended after each batch to ensure optimal performance. Remove the hopper, wipe down surfaces, check the auto lubrication, and inspect the discharge valve for residue.Q: What support is available if I encounter any issues with the machine?

A: Tirupati Plastics offers onsite service support throughout India. Should you encounter problems, you can request maintenance or technical assistance from their certified technicians.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry  Send SMS

Send SMS  Call Me Free

Call Me Free